Because it is the element of a heat pump that is liable for either heating or cooling your household, the compressor is an integral part. If your heat pump’s compressor fails, it won’t be able to control the temperature inside your Cape Town Studio apartment. Listed below are a few warning signs that indicate it may be time to upgrade your compressor.

Your Heat Pump Is No Longer a Current Option

Compressors typically have a life expectancy that varies from ten to fifteen years on average. If your HVAC system is 11 years old or older and shows any failure signs that seem to be reflective of larger issues in the future (for example, strange sounds, short cycling, diminished thermal efficiency), then it is highly recommended that you replace it.

To avoid unscheduled maintenance, expensive maintenance, and lost profits, you should consider removing a faulty compressor that is beginning to fail with a refurbished or fresh unit before the compressor completely breaks down.

On the contrary, when you have an efficient HVAC upkeep program in place, the skilled professionals who undertake periodic maintenance will be willing to offer objective guidance on when it is time to upgrade your compressor. The previous maintenance past, overall dependability, and power efficiency are some of the other vital components that technicians take into consideration in addition to the age of the component.

Your Heat Pump is Only Producing Warm Air

This is among the most typical indications that your compressor must be replaced, so keep an eye out for it. In most cases, the compressor in your heat pump will recirculate the refrigerant, which will result in the heat in your home is transferred to the outside air. A faulty compressor is unable to perform this function to its full potential, and as a result, your HVAC system is unable to cool your home.

Noises and Vibrations That Are Not Normal

When you turn on your heating, ventilation, and air conditioning system, you might hear a recurring rattling or clunking sound. The failure of the compressor is one of the most likely causes of these noises; however, other problems could also be to blame. When you turn on your heating, ventilation, and air-conditioning system, you might also notice that the outdoor unit begins to vibrate.

It is essential to get a new compressor as soon as you observe any abnormalities in the system. This action will help save your system from requiring expensive repairs or going offline completely. You might want to think about getting an expert to inspect your heat pump and give you advice on the most effective way to proceed.

Starting Up the Heat Pump Takes More Time

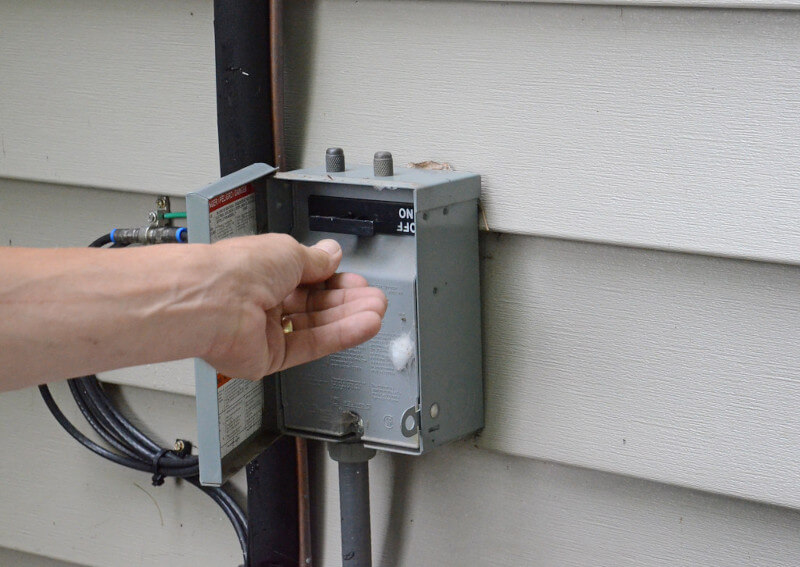

If the breakers in your heat pump burn out or if you have a problem with the compressor, your heat pump may not start. First, a trained technician will check the fuse box to ensure that you do not have a fuse that has burned out, and then they will examine the compressor to determine whether or not the breaker is in working order. You can try turning the heat pump off and then back on again, watching how it reacts each time. If the system still does not fully start up, you should contact a qualified technician here.

The Cost of Energy Continues to Increase

In an industrial, or community facility, an HVAC compressor that is becoming less productive will begin to consume more electricity. This is because the compressor is working harder. As a result, having higher electricity bills could be an indication that you ought to substitute your compressor.

It might appear to be a costly option to replace your HVAC compressor with a refurbished or brand-new unit, but the truth is that making investments in a model that is more energy-efficient typically results in significant savings on electricity costs and reduced carbon dioxide emissions.

Because recent technological developments have resulted in a significant improvement in the energy performance of modern compressors, it is essential to determine whether or not your HVAC system could gain from upgrading to the most latest innovations. The instrumentation capacity control is one example of such a technology. This control modifies the ability of the compressor predicated on the loads that are being placed on the system.

Frequent Electrical Problems

You may have noticed that each time your HVAC system begins operating, the circuit breaker is tripped. The majority of the time, this occurrence takes place right before your compressor completely gives out. By installing a circuit breaker in your home, you can reduce or eliminate the possibility that high-voltage appliances will start a fire there.

Your heat pump will trip the circuit breaker when the compressor stops working properly because it will use an excessive amount of power. If your circuit breaker trips frequently as a result of your heat pump’s operation, it is time to replace the compressor in your unit.

The Fees for the Repairs

The price of repairing an older compressor may be comparable to the cost of purchasing a refurbished device in some cases. Nevertheless, according to the recommendations of the vast majority of industry experts, the compressor should be replaced if the repair price (such as the expense of charging up) is more than fifty percent of the expense of a refurbished unit.

Furthermore, if a substitute compressor is substantially more power-saving than the one that was previously installed in your HVAC system, it may be in your best financial interest to substitute it even if the expense of the maintenance is higher.

If your current heating, ventilation, and air conditioning system have recently displayed any signs of impending failure, the correct way to evaluate its current state is to make an appointment for an inspection with a qualified air-conditioning contractor. In addition to this, make certain that the technician thoroughly inspects and tests the entire network. It would be a waste of time and money to replace certain components, such as fan motors, filtration, and/or ducting, only to discover that these components need to be cleaned or replaced within a few weeks.

Overheating

When you do not care for your heat pump in the manner that is suggested, you frequently cause it to overheat. The heat pump may fail if the overheating is not addressed promptly. A technician must clean the condenser coils and guarantee that your system will keep working properly so that this does not occur. This will help ensure that this does not happen.

Having lines that are twisted or broken, lines that are leaking, or lines that are clogged with copper can all lead to overheating. In addition, the technician will check to make sure that the metering devices are in good condition and that the compressor does not have any moisture buildup in it. If the compressor fails, your heat pump might start to run continuously, or it might not be able to heat or cool your home at all.

Reduced Volume of Airflow

It’s possible that a variety of factors are to blame for the reduced airflow you’re experiencing, depending on what exactly is going on. However, if it is happening with the compressor of your heat pump, the problem is probably caused by a dirty filter. Always make sure that the filters are clean and clear, and make sure to schedule routine maintenance with a qualified service specialist to prevent expensive breakdowns.

Do You Need Professional Assistance?

When it comes to your heating, ventilation, and air conditioning system, the compressors are the component that requires the most attention and care. Feel free to get in touch with one of the helpful and knowledgeable service specialists at GreeDirect if you are unsure about whether or not you require a new heat pump compressor. They will be happy to provide you with additional information. We are ready to assist you right away.